| Contact Us For Quotation | Email: 464560351@qq.com | Whatsapp&Wechat:+8618620373879 |

Musktool-NB /T47013-2015 Non-destructive testing of pressure equipment ultrasonic

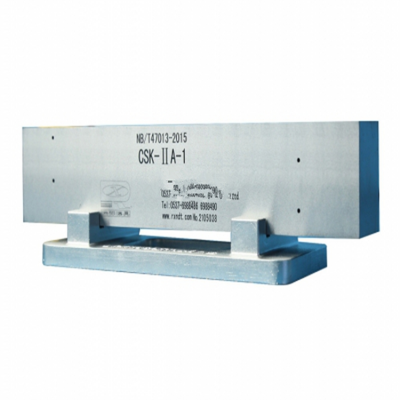

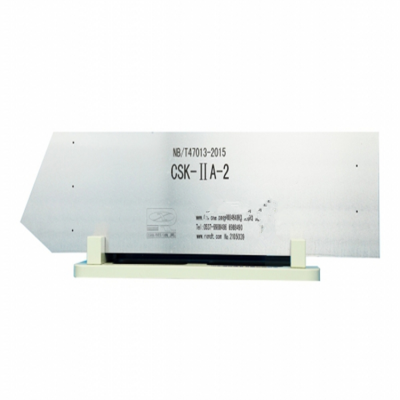

Testing Method for CSK-A-1#

| (1) Setting of shear wave sensitivity: Place the calibrated angle probe at position a in the schematic diagram, move the probe back and forth to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the first point. Place the probe at position b in the schematic diagram, move the probe back and forth to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the second point. Place the probe at position c in the schematic diagram, move the probe back and forth to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the third point. Place the probe at position d in the schematic diagram, move the probe back and forth to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the fourth point. Place the probe at position e in the schematic diagram, move the probe back and forth to make the first reflection sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the fifth point. Place the probe at position f in the schematic diagram, move the probe back and forth to make the first reflection sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the sixth point. The curve formed by connecting the above six points is the reference line specified in the standard. |

| (2) Setting of longitudinal wave sensitivity: Place the calibrated straight probe at position g in the schematic diagram, move the probe back and forth and left and right to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the first point. Place the probe at position h in the schematic diagram, move the probe back and forth and left and right to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the second point. Place the probe at position i in the schematic diagram, move the probe back and forth and left and right to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the third point. Place the probe at position j in the schematic diagram, move the probe back and forth and left and right to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the fourth point. Place the probe at position k in the schematic diagram, move the probe back and forth and left and right to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the fifth point. Place the probe at position l in the schematic diagram, move the probe back and forth and left and right to make the direct sound beam obtain the maximum reflection echo on the Φ2×40mm transverse hole. Adjust the echo amplitude to 80% of the full screen height, record the dB value at this time, which is the sixth point. The curve formed by connecting the above six points is the reference line specified in the standard, and the sensitivity at this time is the reference sensitivity. |

English

English