| Contact Us For Quotation | Email: 464560351@qq.com | Whatsapp&Wechat:+8618620373879 |

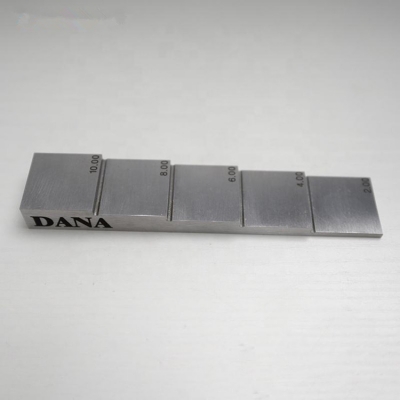

Musktool-DANA 5 Steps Ultrasonic Thickness Gauge Calibration Block 2mm 4mm 6mm 8mm 10mm 20# Carbon Steel 1018 Steel Ndt NDT Ndt

Specification

Features

Multi-step Calibration Design adopts a five-step structure (with thicknesses of 2mm, 4mm, 6mm, 8mm, and 10mm respectively), covering the measurement range from thin-walled to medium-thick-walled. It can complete the full-range linear calibration of the ultrasonic thickness gauge in one go. This design ensures the precise compensation of sound speed, zero position, and sensitivity of the device under different working conditions through standard reflecting surfaces of different thicknesses, avoiding the limitations of single-point calibration. Dual-material Compatibility selects two low-carbon steel materials, 20# carbon steel and 1018 steel. Among them, 20# carbon steel (with a carbon content of approximately 0.20%) complies with common domestic inspection standards, while 1018 steel (with a carbon content of approximately 0.18%) is a low-carbon steel under the American standard. It has a relatively high manganese content and has both good processing performance and structural strength. The acoustic impedance characteristics of the two materials are similar, enabling them to adapt to different standards or customer requirements, ensuring the propagation stability of ultrasonic waves in the materials and enhancing the reliability of the calibration reference. High-precision Processing Technology strictly controls the step thickness tolerance (usually ≤ ±0.1mm) and ensures surface flatness through precision grinding, reducing ultrasonic signal attenuation and scattering. |

English

English